Chemical injection packages are used for a wide range of applications. A large part of these applications is to secure the production process by means of injection of small amounts of chemicals into the production process.

FARAN’s chemical injection package specifications are as follows:

- Designed according to clients’ requirements

- Suitable for viscous, corrosive or toxic liquids

- Suitable for offshore and onshore applications

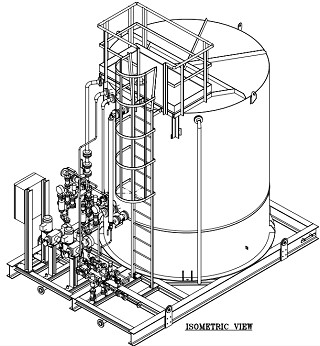

- Fully integrated unit (including tanks, pumps, piping/tubing, valves, fittings, instrumentation and electrical components)

- Simple operation and maintenance

Chemical injection systems typically consist of multiple chemical services with associated single or multi-compartment storage tanks. The chemicals are transferred from the tank to the injection point by means of chemical injection pumps, while flow rates can be adjusted locally or remotely in order to ensure that the correct amount of chemicals is injected.

FARAN’s designed and manufactured chemical injection packages are custom made and based on plunger or diaphragm type injection pumps. The motor of these pumps can either be electric-, air- or gas driven. The packages further consist of a multi compartment tank, suction- and discharge lines valves and instrumentation. The injection rate of the chemicals is adjustable by a variable pump stroke length or a frequency drive of the (electric) motor. Furthermore, FARAN develops skids and packages that comply with both your specifications and international standards (such as ASME, API, and ATEX).

FARAN’s chemical injection package services are as listed below:

- Slug catcher MEG pump package

- Methanol injection

- Caustic solution dosing

- Anti-foam dosing

- Catalyst dosing

- Biocide & corrosion inhibitor dosing

- Hypochlorite dosing package